Babat wrote "maybe the process dynamics is more complicated than I described it". All attention in further development of striation was paid to redistribution of induced current, and nothing was said about distribution of the magnetic field, which generates eddy currents. It means that mechanical oscillations were considered as an effect that triggered striation. This increases current density in the “annular sections” and leads to further fast heating of these zones. Lozinskii writes the following: “Currents from the neighbouring zones (having a width of about one to one half of the depth of penetration into hot steel) which have not yet been heated to the Curie point of the steel attempt to enter those annular sections which are the first to lose their permeability”. However this description alone could not explain the whole process dynamics and in the latest publication Prof. This description allowed explaining the fact that the distance between the temperature stripes drops with frequency increase and supported some other observations. Stresses change electromagnetic properties of material (resistivity in the anti-node area gets lower.) and power in the node areas will be higher resulting in higher temperature. One of the first explanations was that due to magnetostriction effect, the standing waves of mechanical (acoustic) oscillations take place in the part surface. When Babat and Lozinskii met the striation effect, they started a detailed study trying to explain why and when it appears and what might be its influence on the emerging induction surface hardening technology. There were no good power sources in middle frequency range (10-100 kHz) and the selection had to be between tube generators and machines (alternators). At that time in the USSR there was a very tough discussion about optimal selection of frequency for induction heating, especially for surface hardening. This fact is very important for further discussion. Petersburg and were doing a big research on induction technique and technology using HF tube generators. They worked at a large radio tube factory Svetlana in St. Lozinskii and their findings were published in 1940. Conditions for zebra occurrence and it technological importance or limitations are discussed.Įffect of striation was observed by professors G.I. Current presentation provides an overview of available information about zebra effect and gives new explanation of this phenomenon based on existing experimental data and new results of simulation. Wider spreading of induction technology and use of computer simulation of induction processes create a demand and opens new possibilities for study of zebra effect. Only few old induction experts confirm that they observed zebra effect or something similar while a great majority of induction community members never heard about it. Moreover, the authors of this paper did not find any original publications on this issue for more than half a century. There were no complaints from scientists or practitioners regarding any negative effect of zebra phenomenon. There were concerns that zebra effect could set significant limits on use of induction heating for surface hardening due to non-uniform temperature distribution along the part. Several explanations of zebra effect were proposed with not very convincing arguments. It can exist for a relatively long time, from several seconds to several tens of seconds.

Let us call it “zebra effect” for simplicity. They called this phenomenon “polosatiy nagrev” (striation heating).

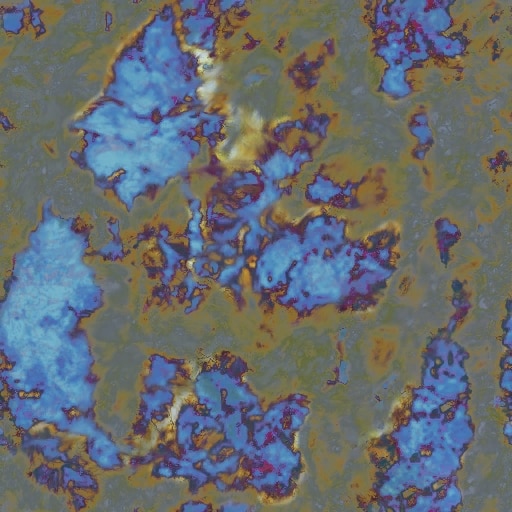

In time these stripes expand and merge, forming a normal temperature pattern.

They reported that under certain conditions one can observe periodical or quasi-periodical bright stripes on the part surface when its temperature passes thru the Curie point. Effect of unstable “wavy” temperature distribution on the part surface during the process of induction heating of ferromagnetic materials was observed and reported by two Russian scientists in 1940.

0 kommentar(er)

0 kommentar(er)